Krautkramer Usm 25 Operating Manual

Operational Quality The DMS Move has happen to be created to offer improved reliability, precision and reportability of width blood pressure measurements in a broad range of programs. Its operational features include: High Performance Width Measurement High measurement balance and dependability ending from zero bridging measurement method. Automatic get control for exceptional repeatability and deterioration supervising.-Built-in heat range compensation algorithm allows accurate measurement up to 540°D (1000°N).Multiple Calibration and Zeroing modes for repeatable accuracy, including: + 2-stage calibration. + 1-stage calibration with Manual on-block zeroing. + 1-point calibration with Autozéroing for every measurement (coupled).

Ge Krautkramer USM 35X Pdf User Manuals. View online or download Ge Krautkramer USM 35X Operator's Manual. USM-25 Manual.pdf - Ebook download. First operating level Second operating level Third operating level Krautkramer USM 25 You can choose between coarse and fine.

+ 1-stage calibration with Usérzeroing in the air (uncoupled). Multiple measurement settings for every applications like: + A-Scan + Thickness + B-Scan + Min / Potential + Differential -Support of several regular probes and the ability to support practically any probe using the custom probe set up feature.Ability to function in harsh conditions with IP67 sealing.

Easy-to-Read Screen -A large screen display, which can end up being modified to supply optimum visibility in differing ambient lighting situations.An 800x480 pixel display, which is certainly better resolution than a regular DVD.A display which has become ergonomically size to assist reduce vision strain.Option of thickness watch, which can end up being either Iarge A-scan with smaller digits or large numbers with smaller A-Scan. Simple Gauge Features The fundamental CL 400 shows the width worth in large éasy-to-read digits. Simple Procedure The CL 5 is certainly a very easy device to operate. The MODE key progresses the user through a series of selection and established up selections and back again to the dimension mode. One press of the Setting key displays a table of regular probes and up to 5 special setups.

Another push of the MODE key shows a fixed up menu where the consumer can conveniently scroll through the menu, find the current configurations and make fast modifications to any óf the displayed settings. A supervisor lock-out function enables a proficient user to arranged up all the speci? M measuring features and configurations of thé CL 5 and fasten the settings so critical settings can not really be changed by a lower level user. Additional advantages offered by this compact, multifunctional device consist of: -Enhanced dimension performance creates highly steady and repeatable width values -Six measurement and screen settings: Regular, Minimum Capture, Maximum Capture, Differential and Rate of reduction, Speed (with CL 5V choice) and Thickness + A-Scan (with Live life A-Scan choice). Snapshot A-Scan on all models -Hollow/Fill width digits displaying coupling or non-coupling position -Visual LED security alarm to notify consumer when measurement are exceeding the consumer selectable limit values -Consumer parameter set-ups for unique con? Gurations and fast device set-up - Versatile power program via standard AA electric batteries or standard rechargeable battery pack program -Multi-language consumer user interface - Auto ultrasonic efficiency (get and door handles) -Wide range of standard probes CL 5 programs The CL 5 will be an easy-to-use accuracy thickness measuring solution for components used in the automotive, modern aviation and aerospace sectors, in particular, like as: -Throw and stamped metal components, age.g. Made of aluminium, steel, copper mineral, bronze -Machined workpieces -Chemically milled components -Metallic strips, metal dishes -Materials and composites -Glass The device can be kept in one hands or placed on?

At workpieces, making the CL 5 the almost all compact way of screening your materials for the required thickness or checking out for page corrosion. CL 5 Compatible Transducer Speci? The USM Go ultrasonic portable downside detector provides been recently ergonomically made to offer an device which is definitely light, small and simple to use in the harshest of inspection environments.

Its ergonomic features consist of; Portability -Little dimension and fat, which permit the instrument to end up being easily managed in restricted areas and places of challenging access.Light plenty of to become carried throughout a whole day's change -Electric battery offers up to 5,5 hrs operation. Can be recharged on- or óff-board. Easy-tó-Read Screen -A screen display which is the exact same size as those in various other GE drawback detectors, also though the instrument is significantly smaller sized than some other equipment in the variety.An 800x480 pixel display, which is better quality than a standard DVD.A display screen with an optimized aspect percentage to guarantee highly described echo separation.A screen which can become easily seen, whether hand-heId or desk-mountéd.A screen which offers become ergonomically size to help reduce eyestrain. Simplicity of Make use of -Can end up being operated with one hands, leaving some other hand free of charge for some other tasks, like as keeping probe in optimum placement or keeping onto ladders.Functions incorporated pressure-sensitive, sat nav joystick handle made from the variety of remote control visual examination equipment offered by GE.

Escalating Efficiency The USM Move functions intuitive operation so there is definitely practically no time-consuming, understanding shape. You are productive from the second you choose it up! Menu is refined making use of the confirmed graphical user interface (GUI) and the revolutionary joystick, enabling one-handed procedure and fast and accurate adjustment. Various other features allowing increased efficiency are: A robust moulded plastic housing to endure the harshest environments and considerably reduce outages. The instrument is dirt- and water-próof to IP67 and is examined to endure shock and vibration. A standard USB connection to allow information to be downloaded from the flaw detector for additional evaluation or storage space.

The device is standard delivered with a 2 Gigabyte SD memory space cards (several cards can become used). Reports are created in jpeg ór bmp format therefore there can be no want for unique reading software. A simple on-board data logger to collect and save thickness measurements. State-of-the-art electronics, including electronic amplifier, rectangular influx pulser (elective) and digital filters for a wide variety of software benefits. Functions: SpotChecker “completes” our existing USLT item range for spot weld testing.

It offers genuine portability with a durable, environmentally protective housing. The key distinction between this product and present spot weld screening solutions is its dimension/weight, ecological protection and user helpful operating.

Unique user user interface to work a directing device by two trackballs Touchscreen procedure for direct access of various features and configurations on a large 8.4 inch LCD. Modern PC interfaces, like USB and wireless connection (WLAN, BlueTooth) Remote handle like USLT 2000 Ease of use for inexperienced inspectors (Application Specific Software UltraLOG) Compatible with additional USLT 2000 solutions Hot exchange battery exchange for constant operation Environmentally protected according IP65 Weight approx. 3.2 kg like electric batteries. Spectification: Storage space Heat -20 to +60 °C (-4 to +140°Y) Working Temperatures 0 to +45 °Chemical (32 to 113°Y) Dimensions W 225 × H 314 × D 94 mm (Watts 8.85 a H 12.36 back button N 3.7”) Weight Approx. 3.2 kg (7.05 lb .) (Incl.

Electric batteries) Security Ranking IP 65 Shock Resistance Based to Durante 600 68-2-27 Vibration Level of resistance Relating to IEC 600 68-2-6 Fc Display 8.4” TFT, SVGA, Touchscreen Control Gadgets 2 × Trackball with 2 Control keys Each, 6 Functionality Keys, Touch screen Connections Probes 2 × LEMO 00 Triax Energy Supply Device 1 × LEMO 0S, 4-flag Socket Network 1 × RJ45 USB 4 × USB Type A Outlet, 1 × USB Type B Outlet Optional WLAN, Bluetooth Power Offer Operating Voltage 15 V DC Strength Intake Approx. 22 Watts Batteries 2 × Lithium-Ion 10.8 V, 4.8 Ah Operating Time Approx. 4.0 h with 2 Batteries Power Supply Unit Outside Power Source Unit 100. 230 V AC, Potential.

70 Watts Ultrasound Pulser Kind Spike Heart beat Pulse Repetition Rate of recurrence (PRF) Utmost. 1,000 Hz, No Constant Pulse Sequence Voltage Max. 400 Sixth is v Initial Heartbeat Rise Time 15 ns Damping 50 Ohm Settings and Assessment Calibration Ranges Min. 0 to 2.5 mm (0 to 0.1”) (metal); potential. 0 to 9,700 mm (0 to 381”) (metal) Sound Velocity Variety 500. 15,000 meters/s (0.02.

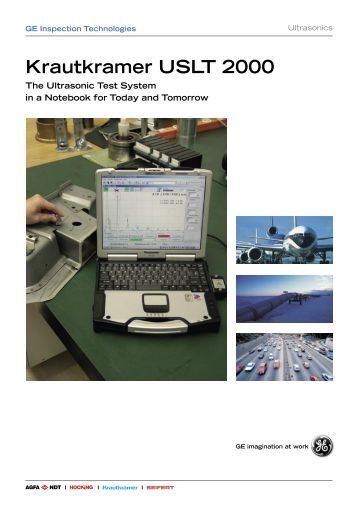

Functions: The USLT 2000 Collection are usually ultrasonic dialog instrument included in a Personal computer having outstanding ultrasonic features, wide frequency variety (0.5 - 20 MHz) and two entrance. Display of thé A-scans on thé PC monitor with a quási-analog A-scán quality of up to 635 x 400 pixels and a high refresh price. Storage space of the instrument settings, check outcomes or total test orders are produced in a database. The USLT 2000 Collection ultrasonic drawback detectors are widely used throughout the motor vehicle sector for spot weld testing. PC-based downside detector Comes along standard as USB, industrial desktop Computer or laptop based devices.

USM Eyesight a overall ultrasonic option to increase efficiency in fresh procedure pipework USM Vision provides a complete digital examination workflow, from the examination plan creation to the information writing that can end up being done wirelessly. USM Eyesight has long been developed to satisfy the market want to transition from radiographic tó ultrasonic weld examination relating to the worldwide rules and standards through: Optimizing the use of specialized inspection staff Increasing efficiency i.at the. Lean processing/construction Decreasing the present weld examination radiographic constraints: light, consumables and chemical substance waste management Simplifying the ultrasonic weld inspection process. Creating a Weld Examination Program No ultrasonic knowledge is required to produce and fill a weld inspection strategy. All that is certainly required will be to describe the inspection job, and enter the fundamental information like as web site location, amount of welds, tube diameter, width and materials, weld planning, method and technique to become utilized. Download commando d day apk hacked. The software program will after that compute and generate all the UT setups required to carry out TOFD and/or Phased Variety examination of the specified welds.These set-ups consist of: Choice of the right probes and wédges from a data source. Setting of the probe.

Positioning of the needed UT guidelines to execute an effective weld examination according to the welding regular and code based treatment selected Analyzing the Weld Examination Data All weld examination data is definitely communicated to an analysis station making use of the Tempo software system. Here the suitably experienced ultrasonic inspector can examine and evaluate the weld examination data, using advanced analysis tools such as real time, volume-corrected imaging, as properly as standard digital tools functions for image analysis, improvement and measurement. In add-on, a variety of dimension and seeing tools will be included within the evaluation software.

Validating a Weld Inspection Plan A specialist qualified in ultrasonic screening must after that confirm the setups. Each weld will be divided in one or many passes with TOFD or Pennsylvania method. The UT specialists have got to validate these goes by by using a Raytracing device.

Micah Meisner directed the video. The video features the English musician performing the new track with Nelly Furtado also appearing in the video. The single became Morrison's most successful single to date, peaking in the top ten on many European charts, in the top three in the UK and Ireland and topped the charts in Germany and Switzerland. Torrent james morrison broken strings free download. The song is a duet with Canadian pop/R&B singer-songwriter Nelly Furtado. A music video in support of James Morrison's 'Broken Strings' has made its world premiere on 17 November.

They also have got the ability to modify them by selecting another probe from the information base, changing the probe(beds) position(beds). When all the goes by are validated, the weld inspection plan can become exported to the order unit. The Phasor series ultrasonic flaw detectors comes available in four different versions with upgraded functions and advantages. Phasor CV can be a code-compliant standard ultrasonic downside detector that can end up being UPGRADED to Phasor 16/16 Weld or to the 16/64 Phasor XS. Upgrading to phased range is definitely a quick and simple software update to Phasor 16/16 Weld or Phasor XS.

No adjustments to the base unit equipment are needed and making use of the same simple menu-driven interface as the Phasor CV model, training is usually minimal. Combined with phased number transducers, both platforms can resolve your most demanding inspection programs in less time at an inexpensive price. Phasor 16/16 Weld and Phasor XS can switch to conventional UT quickly therefore that inspectors can make use of any standard transducer to assess detected flaws (locating and dimensions) to any stipulated regular or check training. The Phasor CV/DM brings together a phased number imaging device and a conventional drawback detector into one device, with a phased number probe, which allows significant boosts self-confidence in rust inspection data Spectification: Internal Memory Set-up files Removable Memory On 512 MB SD Card for report and set-up documents Documentation Structure JPEG 80 KB/picture Weight 3.8 kg (8.2 pounds) with battery power Proportions 282 mm Watts back button 171 mm H back button 159 mm Deb (11.1 in. The most recent version of the USM 35 portable ultrasonic flaw detector from GE's i9000 Inspection Technology business, will be now completely covered against the ingress of dirt and higher pressure aircraft of drinking water to IP 66 and includes new software program which allows its procedure to Western weld inspection standards. Protection accorind to lP66 Can become managed in severe or commercial environments Fast and bright color LCD Standard rechargeable battery power with capability to operate for 14 hrs Max permitted operating heat range range from 0°Chemical to 50°D Optional DGS component for one element or double element (Testosterone levels/R) probes. The module contains some preset GE's single or dual probes.

Some other probes can be set up by the consumer. TrueDGS® angle beam transducers and software for considerably improved dimensions capabilities to EN 583-2.

USM 32X T and USM 32X M: little box, huge performance. Nicely balanced between ergonomics and efficiency: easy solutions for your day-to-day applications. Two versions - which one ánd for whát? This simplicity of use arrives with the 2 various variations on which you will find just the functions you require: USM 32X C for all regular programs USM 32X M for screening large work pieces or strongly sound-attenuating materials Two rotary knobs 14 secrets only Large colour LCD Only one menu range Four features per menus Direct access to all features Help for 20 dialects. The USIP 40 is certainly a precision, multi-channel ultrasonic testing instrument made to provide the maximum in examination self-confidence.

A range of packaging options permit the USIP 40 to end up being set up as an ultrasonic container driven by a remote control PC, an integrated rack bracket device, or as a electric battery powered portable instrument. Combined with various application-specific imaging and analysis equipment, the USIP 40 offers the ultimate remedy for all of your examination needs. Obtainable up to ultrasonic 10 channels Up to 20kHz PRF EchoMAX-never miss a chance Backwall indicate attenuator Direct 3 axis encoder insight Interface door synchronizing for surface area adhering to Multi-language enabled Aerospace managed settings to GE G3TF22, G3TF35 and Rolls Royce RPS 705 Automatic gain control. The StressTel BoItMike III ultrasonically measures stress and clamp weight of threaded fasteners. A large, brilliant, easy-to-read display; speedy calibration and set up; and automated temperature payment ensure fast, repeatable and precise fastener pressure measurements in several diverse applications.